Hazcom Basics

This guide provides a general overview of OSHA’s Hazard Communication Standard commonly called HazCom, which addresses chemical safety requirements in the USA;. It is intended for informational purposes only.

Guide Contents

- What Does OSHA Stand For?

- What is OSHA’s Hazard Communication Standard?

- The Addition of GHS to OSHA’s Hazard Communication Standard

- Responsibilities of Different Groups under HazCom 2012

- Classification

- GHS Pictograms

- HazCom Labels

- Safety Data Sheets

- HazCom Training

What Does OSHA Stand For?

OSHA stands for the Occupational Health and Safety Administration which is part of the US Department of Labor. OSHA sets and enforces workplace health and safety standards including the Hazard Communication Standard.

What is OSHA’s Hazard Communication Standard?

The Hazard Communication Standard is an American-wide system that has been in place since 2012. It’s based on the principle that workers have a need and the right to know about the hazardous materials that are at their workplace, as well as the appropriate protective measures to prevent unwanted health effects.

The Addition of GHS to OSHA’s Hazard Communication Standard

GHS stands for The Globally Harmonized System of Classification and Labeling of Chemicals. GHS was created by the United Nations as an international standard. In the past there has been variability in classification, as an example, two products with similar ingredients may have an SDS and label that are quite different depending on what country manufactures them. That confusion is avoided because of GHS. Now everyone will use the same criteria. How chemical products are classified is better defined. Hazard phrases are provided in standardized direct wording, and it is easier to find the information you are looking for. The information always appears in the same place on labels and SDSs. This will reduce confusion for workers everywhere.

OSHA’s Hazard Communication Standard adopts and integrates the elements of GHS into a USA standard called HazCom 2012.

What is the Globally Harmonized System (GHS)?

The GHS is a system for harmonizing hazard classification criteria and chemical hazard communication elements worldwide. The GHS is not a regulation; rather it is a framework or guidance for classifying and labeling hazardous chemicals. The purpose of classification under the GHS is to provide harmonized information to users of chemicals with the goal of enhancing protection of human health and the environment.

Around the world countries have regulatory systems for chemical classification and hazard communication. The systems may look similar, but their differences can lead to multiple interpretations and inconsistencies for a classification, label, and Safety Data Sheets (SDS) for the same product. Moving to one standard in the age of global trade simplifies regulations and improves the safety for workers who interact with hazardous products.

Hazard Communication Standard after GHS

The Hazard Communication Standard requires:

- Chemical suppliers to evaluate the hazards of the chemicals they produce and classify them as physical and/or health hazards.

- Suppliers also need to prepare labels and safety data sheets to be shipped with their chemicals that convey the hazard information to their customers.

- All employers with hazardous chemicals need to ensure the chemicals in their workplace have labels and Safety Data Sheets available for their workers.

- Employers need to train their workers on how to safely handle the chemicals in their workplace.

- Employers also need to prepare a list of hazardous chemicals at the workplace and develop a written hazard communication program.

GHS Elements in OSHA’s Hazard Communication Standard

|

Signal Word (Listed on SDSs and Labels) |

Danger (more serious hazards) Warning (less serious hazards) |

| Classification |

Health Hazard Classes (12 categories) |

| Safety Data Sheets (SDSs) | 16-section format Order is very structured and specific Signal words (Warning or Danger) Hazard and Precautionary Statements Hazard Pictograms |

|

Red Square 45° |

|

| Primary Label |  |

Responsibilities of Different Groups under HazCom 2012

OSHA’s HazCom 2012 incorporates a flow of information from chemical suppliers, downstream to employers, and ultimately workers.

|

Suppliers: Manufacturers, Distributors, and Importers

|

What are supplier responsibilities?

|

|

Employers

|

What are employer responsibilities?

|

|

Workers

|

What are worker responsibilities?

|

Classification

Most of the hazard classes adopted by OSHA HazCom are common to other countries that have implemented GHS. The HazCom approach to classification assigns a product to a group and then to a category and finally a class. HazCom has two main groups of hazards: the physical hazards group and the health hazards group. There is also a third GHS group called the Environmental Hazards Group that is not used at this time. A product can have more than one hazard group classification.

Physical Hazards Group: chemicals in this hazard group present significant physical danger. Products are classified based on their physical state (solid, liquid, gas) and physical properties (explosive, flammable, corrosive).

Health hazard Group: chemicals in this hazard group present health danger either in the short term or long term.

Example: Methanol Classification

|

Group |

Class |

Category |

|---|---|---|

|

Physical Hazard |

Flammable liquid |

2 |

|

Health Hazard |

Acute toxicity (Oral) |

3 |

|

Health Hazard |

Acute toxicity (Dermal) |

3 |

|

Health Hazard |

Acute toxicity (Inhalation) |

3 |

|

Health Hazard |

Eye Irritation |

2B |

|

Health Hazard |

Reproductive toxicity - Effects on or via lactation |

1A |

|

Health Hazard |

Specific target organ toxicity (single exposure) |

1 |

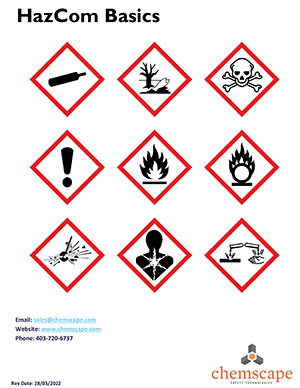

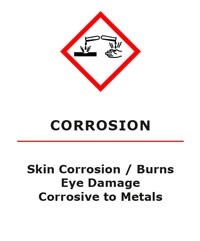

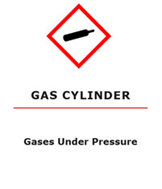

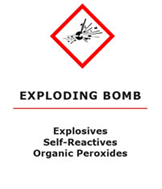

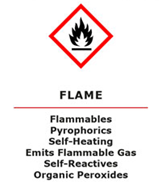

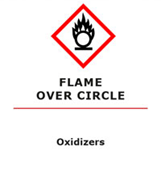

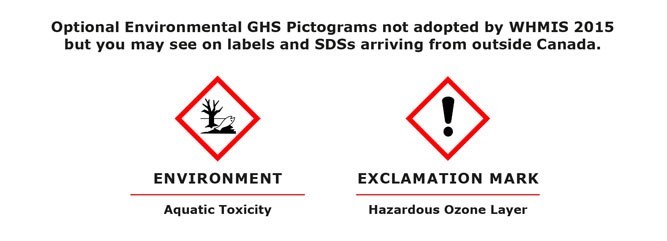

GHS Pictograms

GHS pictograms are graphic images that show you what type of hazard is present. They are organized according to the hazard group category. A chemical may have more than one pictogram.

Health Hazard

Physical Hazard

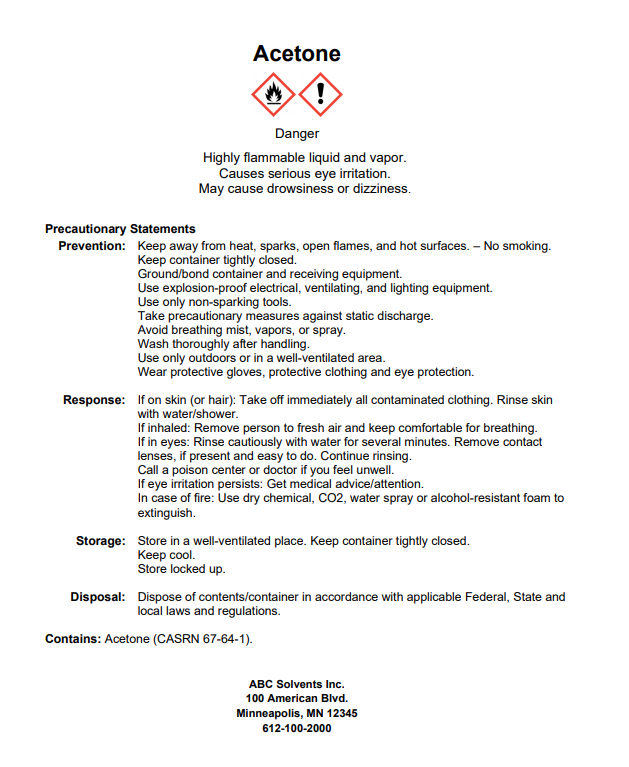

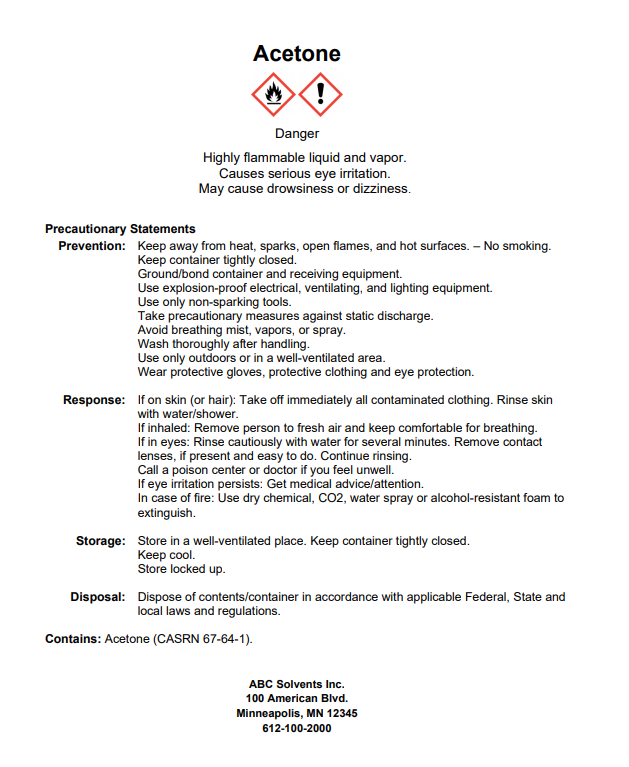

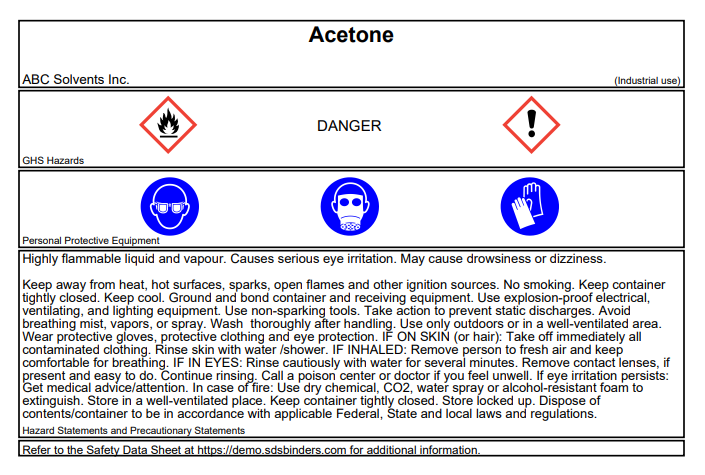

HazCom Labels

In the Workplace there are several types of containers that have different label requirements.

There are shipped or primary container labels, workplace or secondary container labels,

stationary container labels like tanks and pipes, and portable containers which have NO label requirements under HazCom.

What are primary labels?You should see a primary label on every container of hazardous product that you use on the job. There are 6 required elements that need to be on Shipped or Primary labels this includes:

|

|

What are secondary labels?Suppliers may need to apply a secondary label to a product when:

|

|

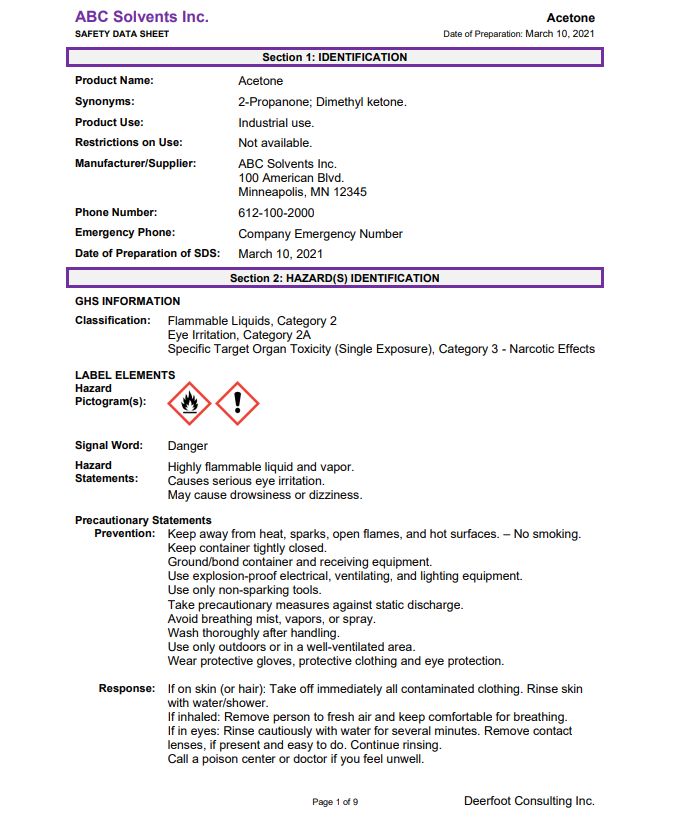

Safety Data Sheets

The Safety Data Sheet, also known as the SDS is a document that helps you to identify hazardous materials and gives you full details on what the hazards are. SDSs provide detailed hazard information about the product than the label and instructions on how to work safely with the hazardous product. It spells out the steps you need to take if there ever is an emergency.

What are the fundamental questions answered on an SDS?

|

Here are some basic questions you need to be able to answer before you work safely with a product:

|

|

Important Questions to Ask when Reading a Safety Data Sheet

When you read through a Safety Data Sheet there are certain questions you should ask to ensure you have a thorough understanding of the product. The information on the SDS may prompt follow up in other areas of your health and safety program.

Identification

- Do I have the correct SDS for the product and for the country?

- Do I have the most up to date SDS for the product?

- Does the SDS description match the product I have?

Potential Hazards

- Can this material burn or explode?

- Is this material unstable? If so, under what conditions?

- Can this product react with other chemicals? If so, which ones?

- How can this product harm my health?

- What are the symptoms of exposure?

- Do I need a discussion with my doctor on the health effects of the product?

Preventive Measures

- Do I need engineering controls?

- Are there any special handling precautions?

- What PPE is recommended?

- Do I need to be careful when mixing this material with any other chemicals?

- Are there special storage conditions?

Emergency Measures

- What do I do in a fire or explosion?

- What are the first aid measures if I am exposed?

- What do I do in a spill or leak?

- Where is the emergency response equipment?

HazCom Training

HazCom training is frequently done when employees are hired as part of their orientation to a new company. Although there is no standard or expiration for HazCom training industry best practices recommends HazCom training should be ongoing, reviewed at least annually and adapt as hazards change in the workplace. A good HazCom training program incorporates dialogue between the employer and employee with engagement and dialogue between management and front-line workers.

HazCom training should incorporate:

- Roles and responsibilities

- Discussion on workplace Chemical Hazards, how to handle and store properly

- Classification and GHS pictogram awareness

- Safety Data Sheet education

- SDS labelling requirements

Training needs to be done to make it workplace specific and practical to the employees. Examples of regular training can include review of the location hazard communication plan; emergency drills and standards; annual chemical inventory; and regular toolbox talks on chemical safety relevant to the workplace.

Download the Full HazCom Basics Guide

To get your own copy of Chemscape’s HazCom guide, download the free PDF today.

Need Help Implementing HazCom?

Chemscape has many tools to help organizations with their HazCom implementation and compliance. Chemscape provides SDS Authoring services to suppliers, has an online SDS Management system called sdsBinders to keep your inventory up-to-date and compliant, and Chemscape has an online HazCom course many of our sdsBinders customers use. Chemscape also has an online chemical management program called CHAMP (Chemical Hazard Assessment and Management Program). Chemscape’s CHAMP system provides hazard assessments on your chemicals and offers recommendations on controls to reduce risk. Chemscape provides Industrial Hygiene Services to coach clients on chemical management best practices using our technologies.